Belt Sander Tips

The belt sander was a staple in many wood working shops in time gone by. Generally they were viewed as noisy, dusty and too aggressive, but we used them because they were the only game in town.

I have two belt sanders that I turn to when I am looking to remove lots of rough wood, or glue. I confess to not having thought about the newer features or considering replacing my old standbys.

As I watched the video I was taken with the improved quality of the dust collection and I'd never really thought of the advantage you get with variable speed.

The video above shows a really good solution for life in a small work shop. A platform like the one in the video adds versatility to your sander at very little cost.

+++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

A foot note on today's blog is the work that I am doing in our garage. I am building a 12 foot by 4 foot platform/deck 3 feet hight inside our garage to take advantage of our garage's very high ceiling.

In the front of our two car garage is a freezer and two sets of off season tires. (tyres). Once the deck is complete the tires and recycling containers etc will be underneath and the freezer and storage rack will be on top. Effectively we will increase the available storage space in the garage by 48 square feet. Wouldn't everyone like 48 more feet of storage?!

I worked for a couple of hours in the cold building the frame and legs for the deck. This is a job that I should have done earlier in the year.

The legs still need to be braced before moving the deck into place and screwing 3/4 inch sheet stock on top. Working with the 2 x 4 sometimes make me think that I am not a wood worker, but a weaver. I had pretty good 2x4s, I picked most of them myself and they still have so much internal tension that they twisted as I was working with them.a

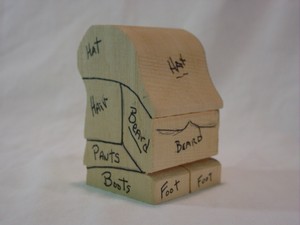

Once my hands got too cold I came inside and worked on Bufford, he got a shellac coat and I've begun to paint him. If I get some quiet time over the next couple of evenings he should be done by the end of the week too.

I have a couple of days away from the shop, but I hope to be finished the build by Friday and maybe get all the stuff moved on Saturday.

If you are where the snow is, shovel carefully. If are where there is no snow, lucky you.

cheers, ianw