If you do not have a marking gauge this is perfectly decent tool with which to experiment. The price is good and the tool is basic, it uses a pin to scribe the line instead of a mini knife blade which does not sheer as well but is easier to set and sharpen. There are nicer looking gauges out there, gauges made from exotic wood, or with multiple blades for marking tenons in one go but this one will get you started. Not only that if you do decide to spent 2 or 3 times as much money on another gauge, keep the expensive one for really fine work and use this one on rough lumber. I now wonder why it took me so long to discover the value of these tools.

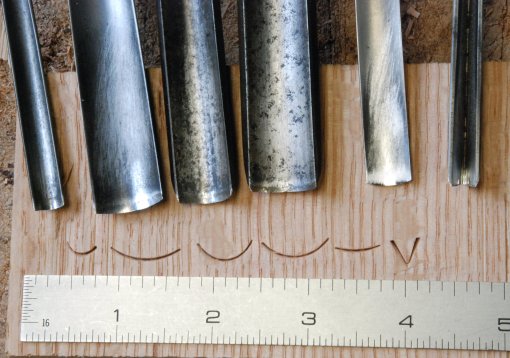

These are not great chisels, you can't get great chisels for cheap, really good chisels cost $50.00+ each. However, you should not need to buy good chisels more than once or twice in your life if you are a typical woodworker.

Why buy cheaper chisels? They are the ones upon which you practice sharpening until you find the system that works for you. These chisels will let you know if you have learned how to sharpen, they just won't stay sharp for very long. Generally the quality of steel and care in tempering is directly related to the price you pay. These chisels are the ones you lend to other people, or that you use to hack out a mortise when building a deck.

A foot note regarding chisels. I have bought a couple of very, very nice old chisels in flea markets. My rule is not to spend more than $10.00 unless the chisel is in great shape. I've purchased a couple of chisels for very cheap that still have good steel left in them, and I also bought a couple were all the good steel has been ground away, or maybe they were just crap from day one. Frankly, I find the thrill of of gambling on an old tool way more rewarding than buying a lottery ticket.